This month’s post is by Ben Davidson of Columbia Gorge Book Arts. Find his great work here and consider joining the Type of the Month Club! Bamboo type is great to print with.

A few years ago I began making type out of bamboo. I've been a sustainable artist and wood worker for most of my life so I naturally drifted towards wood type and wanted to find a way of making it as environmentally friendly as possible. Not to say that other materials being used are better or worse– end grain bamboo just checked a lot of boxes for me with some unexpected benefits, including being able to retain a high level of detail, and that it is even self-healing! Here's a little about my process.

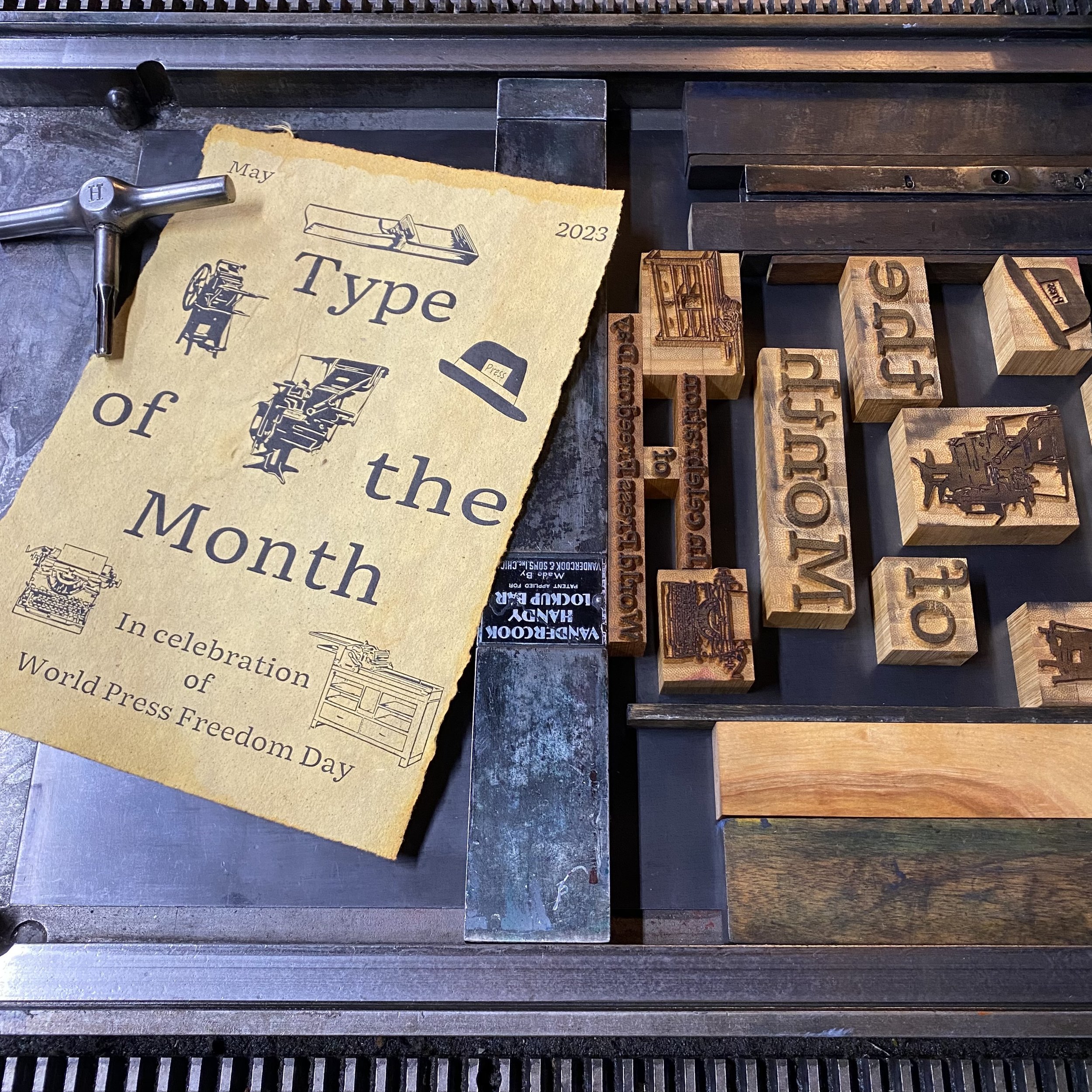

I usually start with some really quick sketches to help me visualize what I'm making. In this case I referenced my own machinery alongside historical images to help with perspectives (I often really struggle with drawing). Once I'm happy with something I'll re-draw a final version, ink it, then digitize it so it can be programmed into g-code for the CNC machine to read. I always carve a trial cut first and print a proper specimen before moving on to production. If everything checks out I'll continue with processing material.

I buy my bamboo from a responsible grower – it is not a food source, and doesn't contribute to loss of habitat. It is shipped to me in bulk once a year (trying to limit the carbon foot print) as 1” thick end grain boards. I square up the boards on a type saw then mill both sides flat on a high speed milling machine; the finishing pass takes the material down to 0.918” resulting in a burnished surface. The height is confirmed with both calipers and a type-high plate gauge.

Next is finishing the surface so it's suitable for printing. Since bamboo is a grass, the surface needs to be thoroughly sealed, otherwise the capillary action of the fibers will draw the ink completely through the type and cause it to weep out the other side! I'll sand the surface using micro mesh sanding pads, starting with 1500 then ending with 3600 grit, then on to French Polishing, a technique I learned from building stringed instruments in Lutherie school. I prefer to dissolve the shellac flakes with denatured alcohol in a wine bottle with a carved v-groove down the side of the cork. This allows me to dispense a small amount at a time; I'll apply three coats, sanding in between with 3600 grit.

After the finish has sufficiently cured it's back to the type saw to cut the finished bamboo into “bars” at previously determined widths for the desired line size. These are then clamped in a CNC milling machine. First, the design is carved into the face of the type at a 60° angle; this prevents the edges from fraying. In the next process the body of the type is precisely trimmed out by the milling machine. Nicks are cut on the type saw.

Finally the body of the type is cleaned up with a chisel and honed with a hand cranked flat sander. Carbon copy proofs are made, the maker's mark is carved, and the type is then oiled with a liberal amount of jojoba oil before shipping.

Thanks for reading and happy printing!!