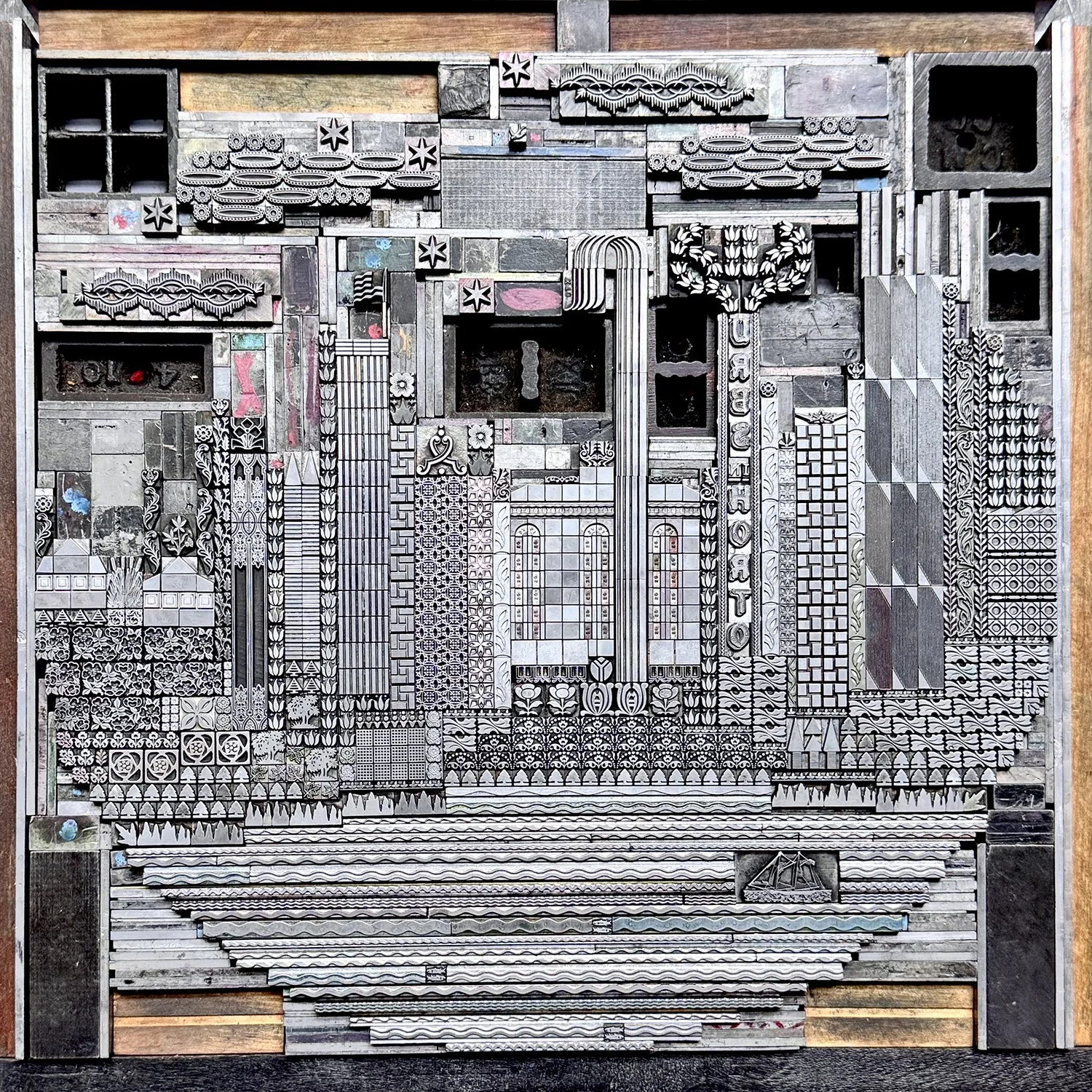

The metal type ornament collection at Starshaped is something that sparks joy and pride in me. For the past 25 years, I’ve amassed a substantial number of these tiny upright soldiers, with a curator’s eye. Nearly every set that comes into the studio starts with the question, ‘how are you going to pay the rent', meaning ‘does this ornament enhance the type of work that Starshaped does?’ Given that space is a premium, I don’t take everything that comes my way if it doesn’t answer YES to this question.

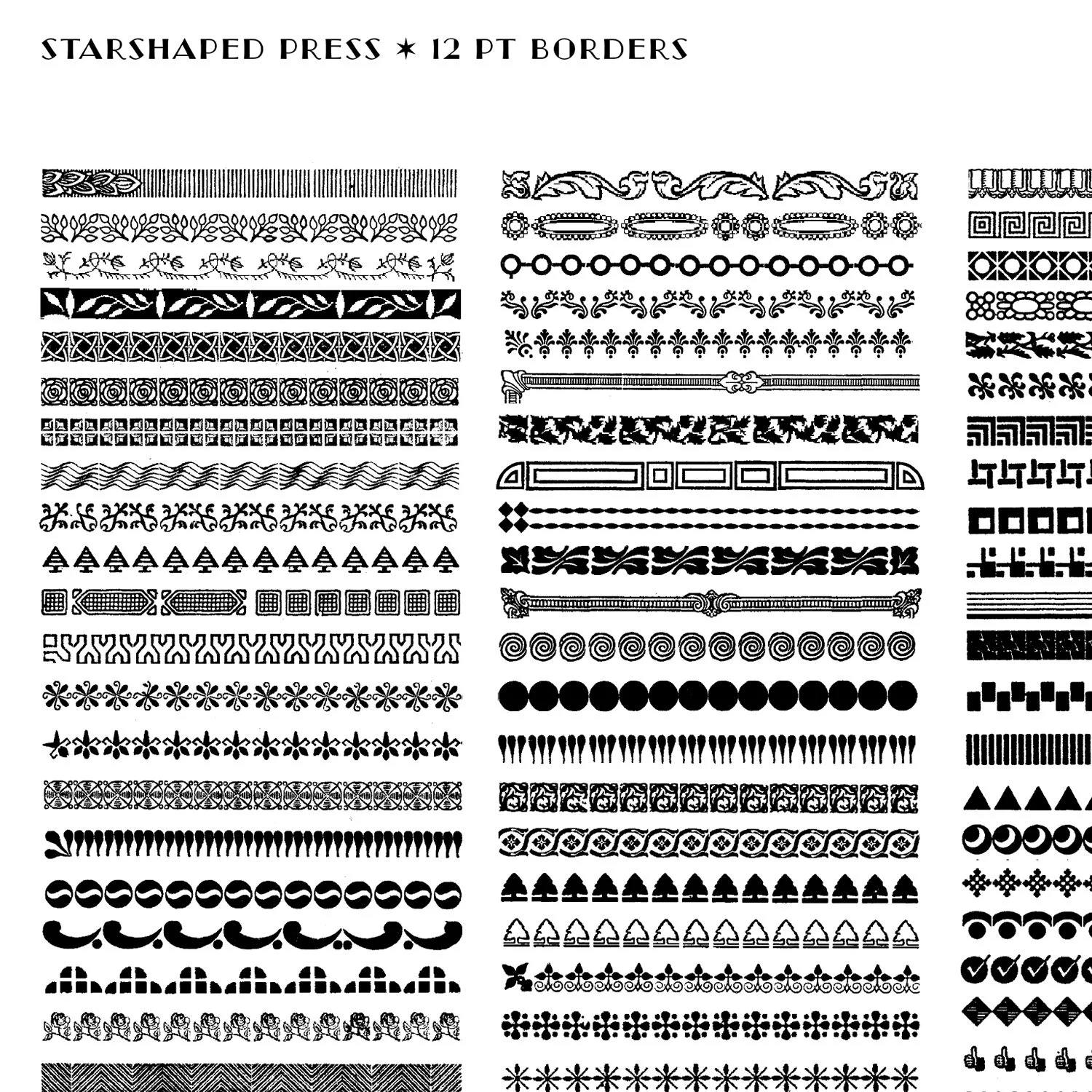

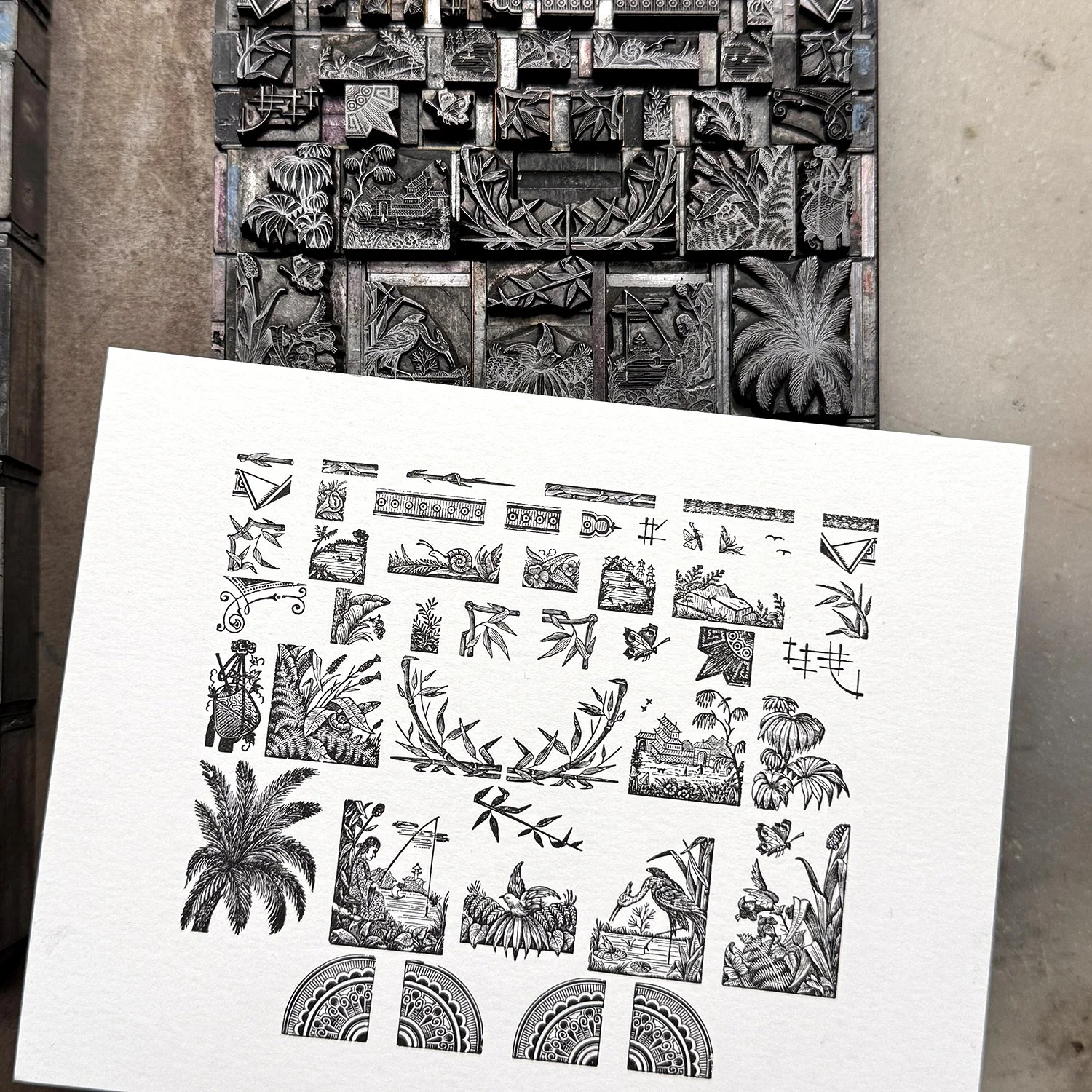

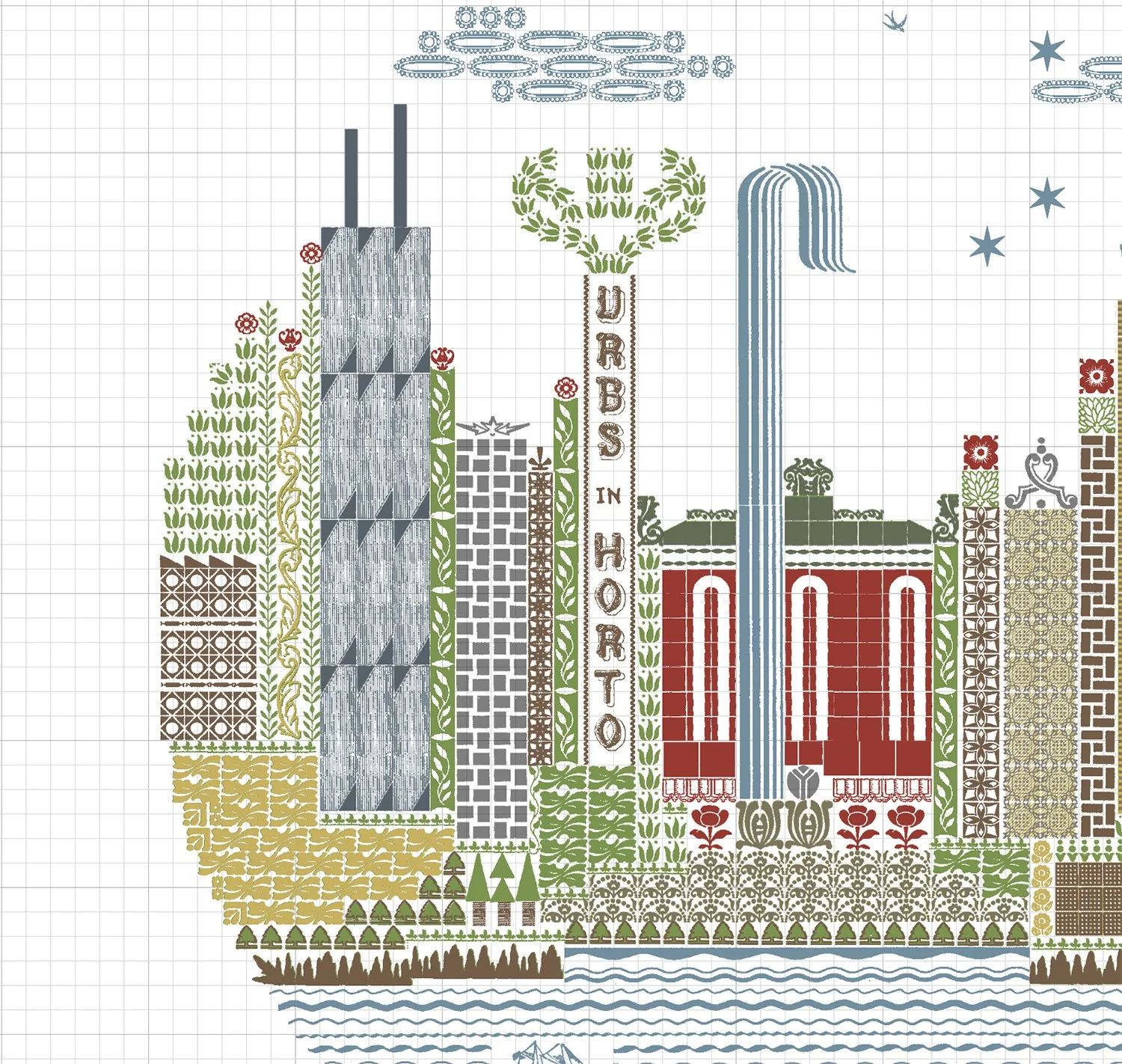

All type and ornament coming into the studio is proofed in black and white on cards so there’s a visual record of what’s available. This also makes it possible to scan them for designing digitally.

One set of proof cards goes into the large binder ring for use in the shop, and another is scanned so there’s a digital record from which to design. I compile a short list of ornaments in one file so I can easily pull the styles I need for a project. Below is a snapshot of one of these pages.

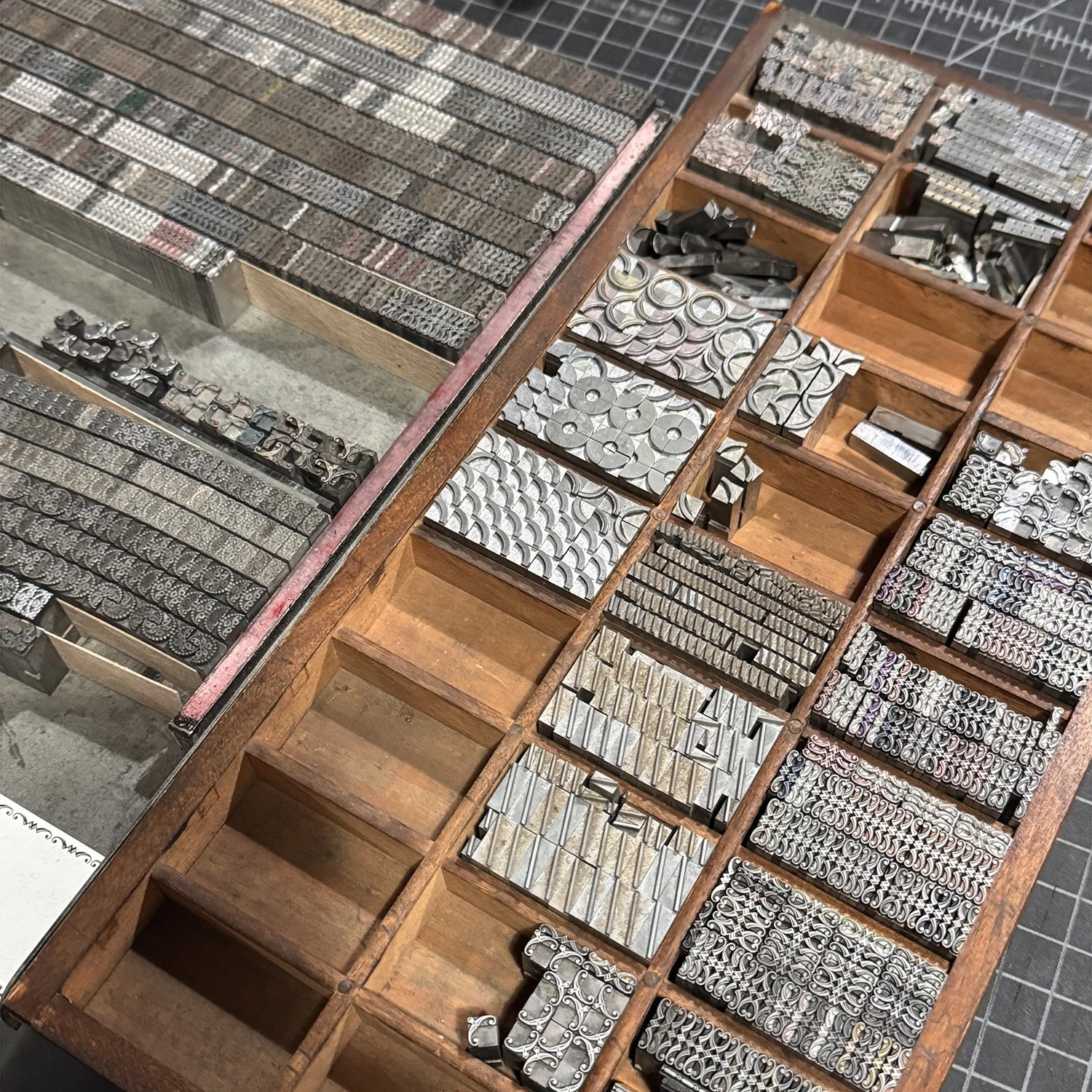

The bulk of the ornament collection is in one place in the shop, with exceptions placed on galleys, in larger type cases and various homemade shelves. The closer they are together, the easier and faster it is to work, so this winter I set about reorganizing the collection to make it more intuitive. Last summer, I acquired new quarter case cabinets to further expand storage space. Quarter cases are sized to fit 4 in a standard open case and are perfect for ornaments as these collections can get heavy. They have their own cabinets (if you’re lucky; they can be hard to find) and you can pack a lot into small spaces.

My goal was to put like with like as much as possible, such as all the miscellaneous sorts of one point size or ornaments that are similar in style. Seasonal sets and those less used can be placed together and higher up (less accessible) as they require minimal viewing. And new-to-me sets needed to fit into the cases to begin their Starshaped tenure.

I stacked the new cabinets (yes I painted them red) and started to make tape notes on what could go where and what was moved. Once starting, there’s no going back, as all cases must be labeled as soon as possible. Not marking where something goes means it’s lost in a sea of thousands of other ornaments.

This process means making a lot of decisions quickly, as well as having multiple cases out at the same time. It’s like a little ornament dance across the table as they slowly find their partners. There’s no easy way to do it. And much like a home remodel, it’s more effective to have lived with the space (ornaments) to understand one’s traffic patterns before reconfiguring a layout.

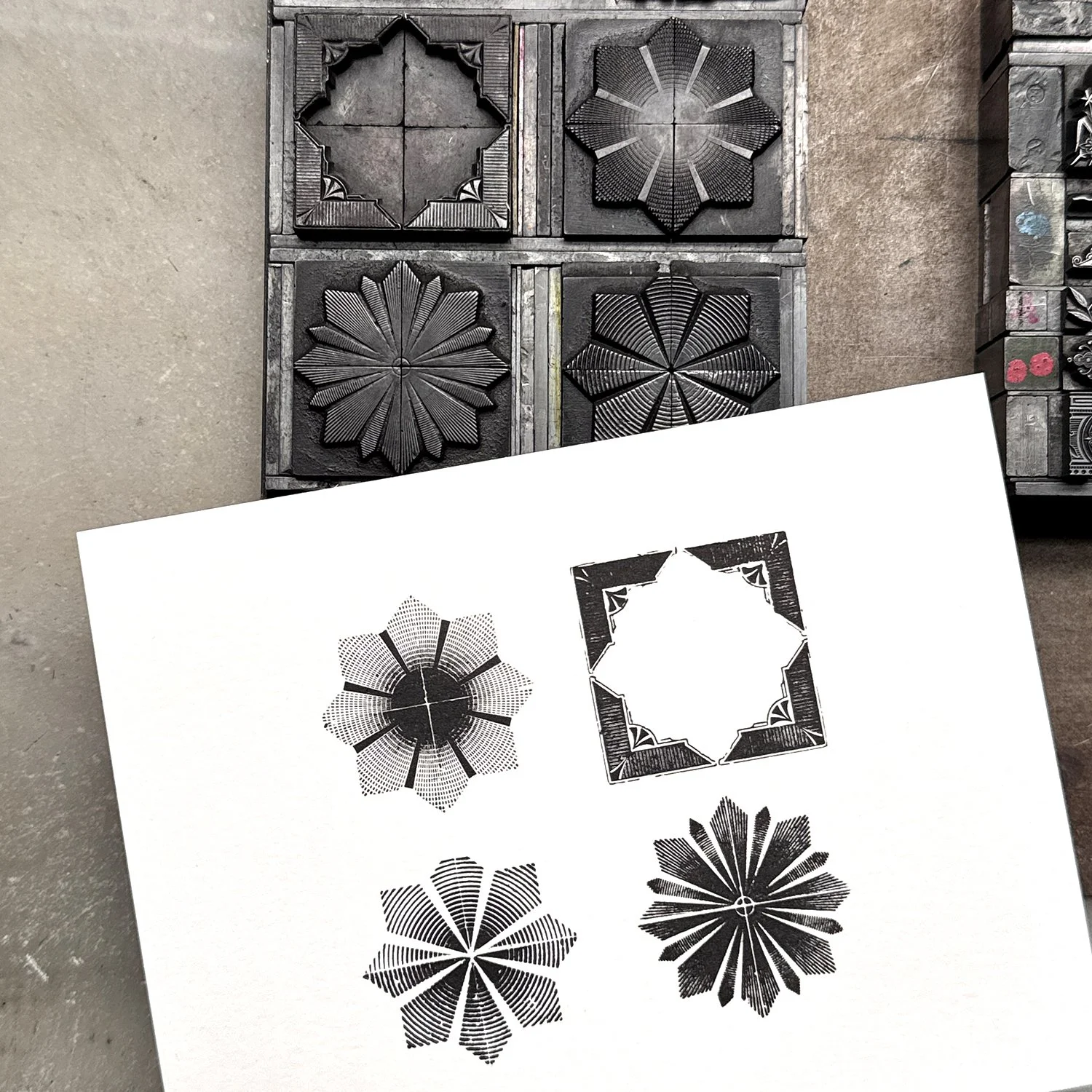

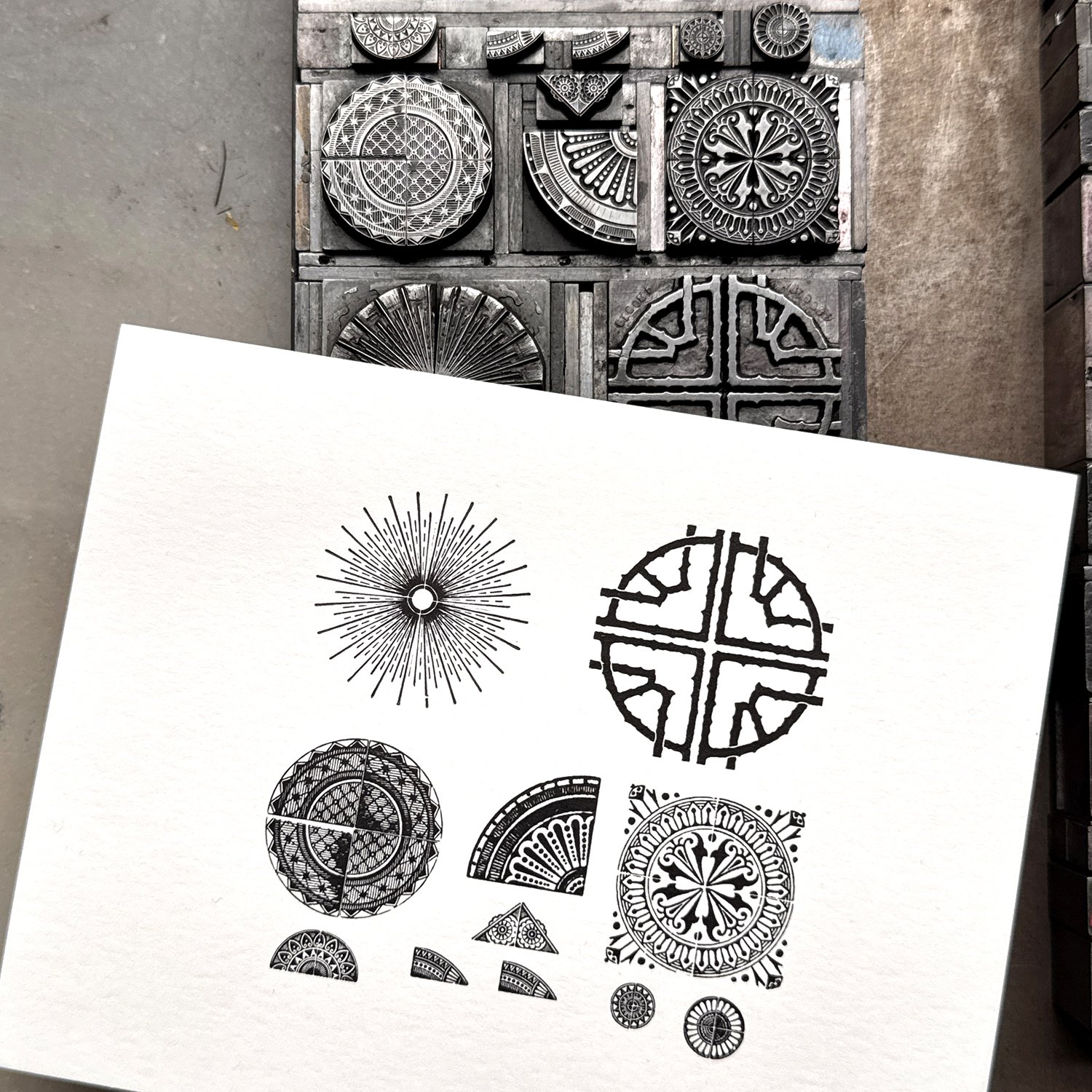

The satisfying part is compiling similar ornaments that have come into the shop at different times from different sources and getting them together as they ought to be. And lining up two color sets (like below) makes it easier to know I have both colors needed for the intended design. Two-color designs were incredibly popular for holiday printing and many still have hints of red and green ink on them from years past.

I also used boxes to help keep sets together and to move them close to whatever case was about to receive them. Some of the ornaments in quarter cases moved to other locations, such as galleys that hold larger quantities of a single design or handy boxes that are less frequently used.

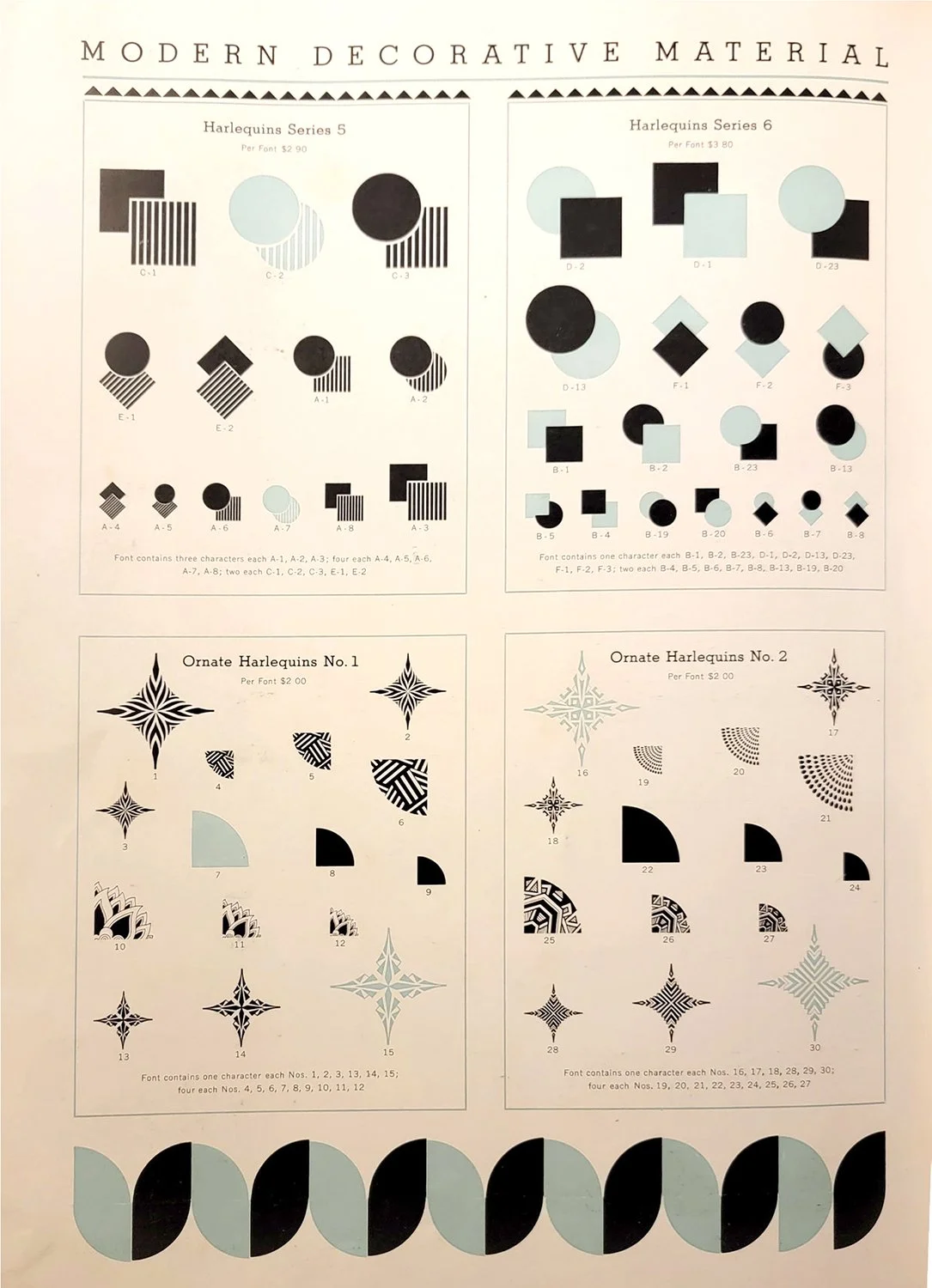

The fun of handling ornaments is identifying them. Some were made at a very specific moment in time, enjoying a fleeting popularity before receding into design history. One example is ‘Harlequin’ ornaments, as shown by this specimen page provided by Val at Bowerbox Press.

A deep clean of the sets in my shop revealed that they’re sadly in poor shape. Perhaps they were used extensively in the past or jostled around too much, smashing corners of various sorts. We can only imagine what kind of history they have.

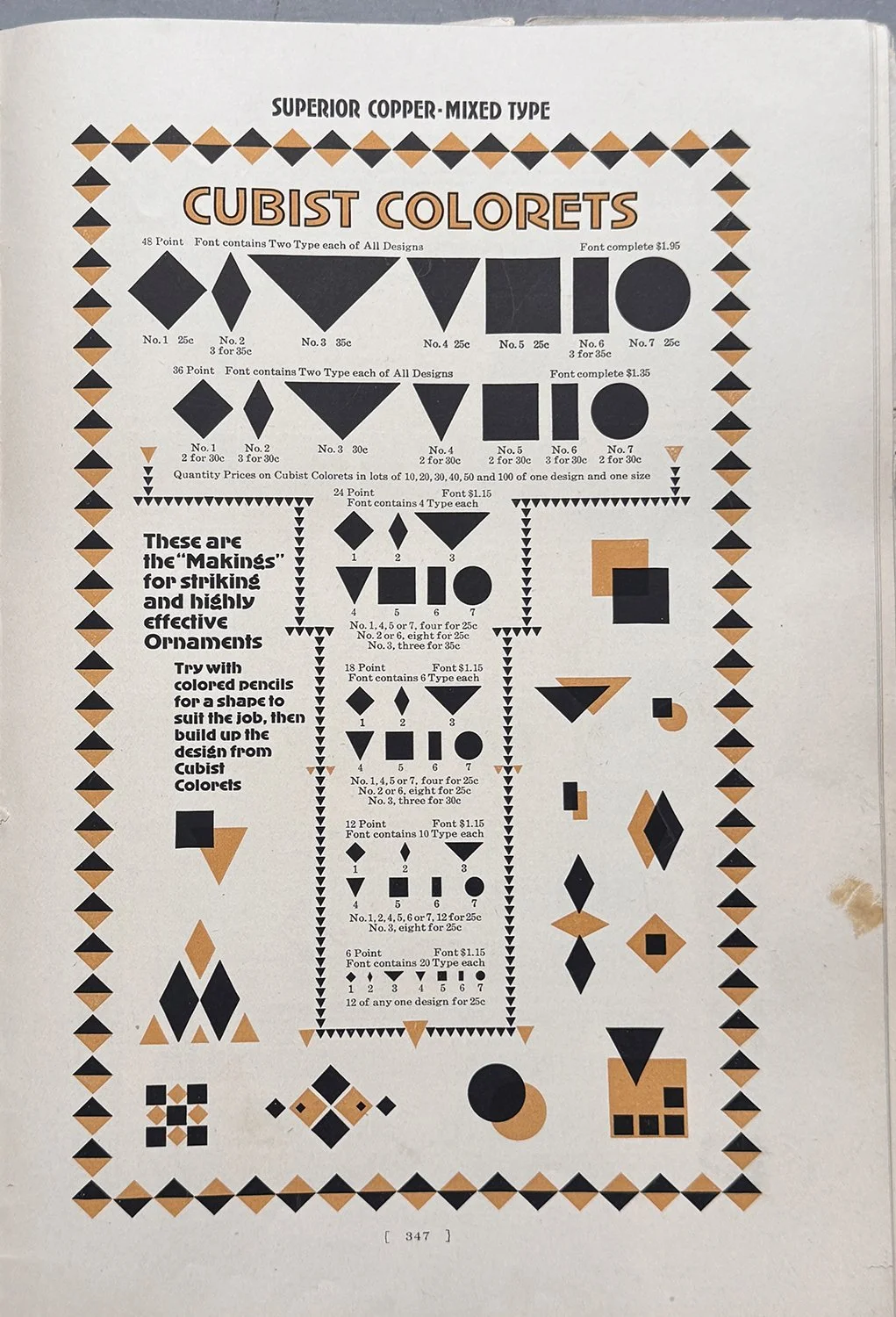

Others became workhorses that shifted from a unified collection to being separated by style. Case in point is ‘colorets’, a term I’ve found across multiple specimen books and shifting over time to represent a range of basic shapes. I chose to separate the ones I have collected to cases for circles, triangles and squares. This makes it easier when designing to grab the case that is most likely to have the shape I need.

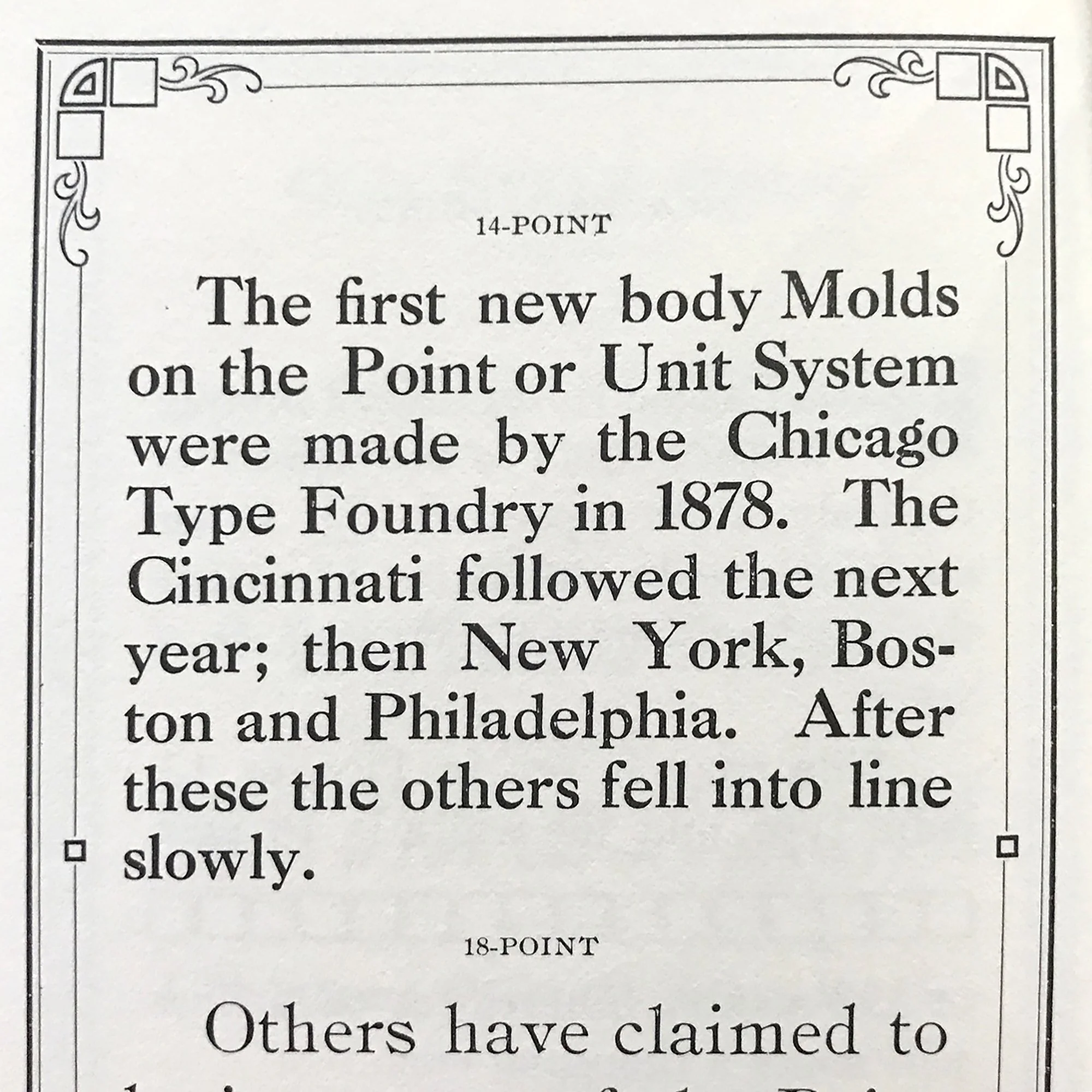

After sorting ornaments, it’s time to proof any that are new or have slipped through the cracks over time. This included a lot of my 19th century type collection.

Below are two nearly-complete sets produced by Mackellar, Smiths & Jordan (Philadelphia). While I have often referenced them in a specimen book, having a print of exactly what is in my collection, in a way that can be annotated for the number of each sort, is much more helpful for design work.

Other ornaments have been grouped together for proofing, even if they may have existed as part of different sets at some point. Some of these are very dirty and still require more cleaning and some are damaged in ways that might make them difficult to work with in the future.

Here are most of the final results of this project! The labels are digital composites of all of the proofs of the ornaments so that I can squish as many as possible on them. There’s still a little space in many of these to expand if needed.

One other homemade quarter case cabinet is in another area and I’ve used it to consolidate random cuts and other small sets that don’t get as much day-to-day traction (a collection of telephones, anyone?) There are also galleys with larger ornaments or those with a substantial number of sorts that don’t make sense filling entire quarter cases.

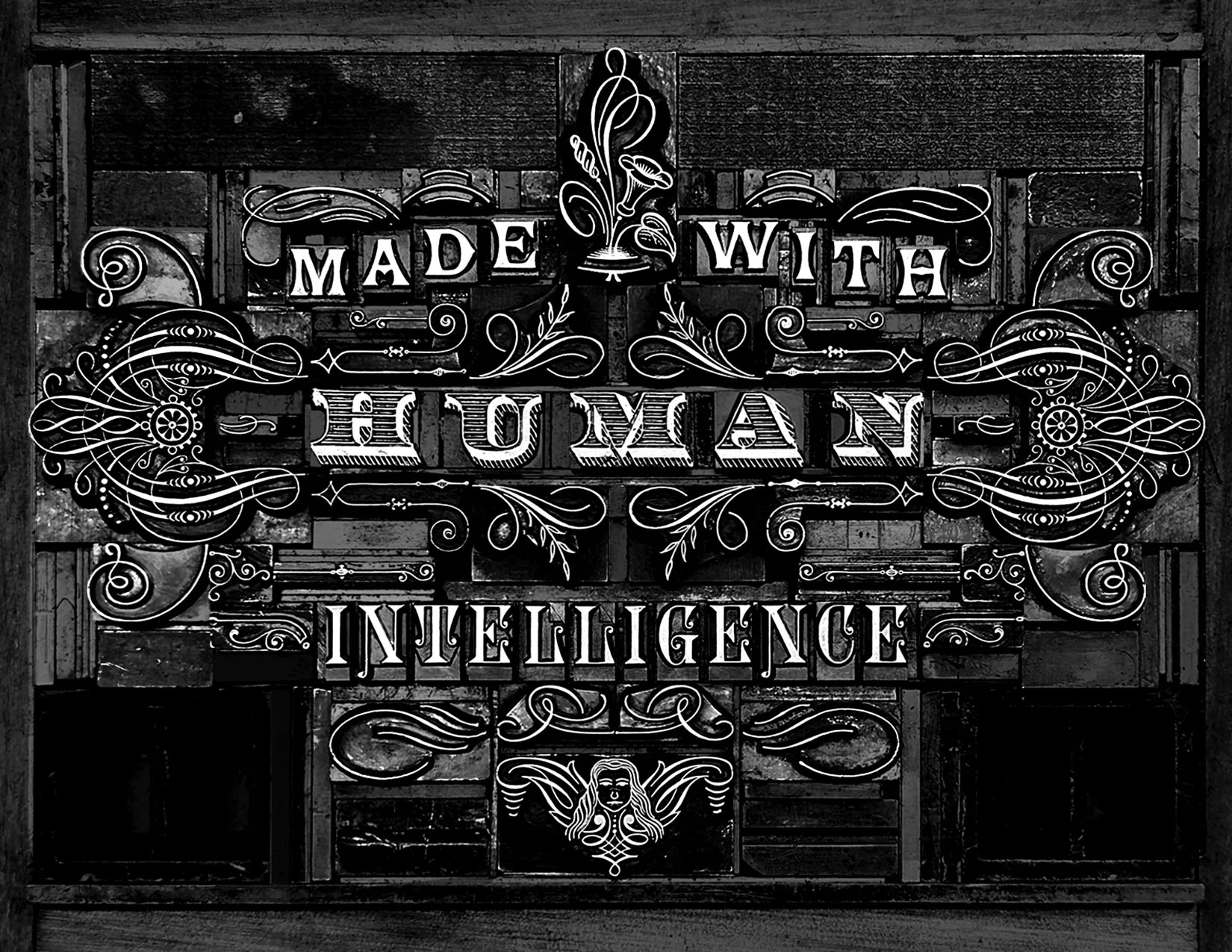

Overall, this process took a lot longer than I budgeted time for, making it stressful and exhausting. While attempting to make smart choices about where ornaments intuitively belong, I won’t fully know if I nailed it until I’ve done a number of projects. Having completed two major prints so far this year, I did find it faster and easier. The reorganization is promising!

The pleasure of this project is having had the opportunity to touch everything again, improving a physical connection with the collection and sparking new ideas for ornaments I haven’t thought about in a while. It’s true that sometimes you have to see things in new ways (or new places) to forge a path forward. It’s a welcome refresh for a new year.